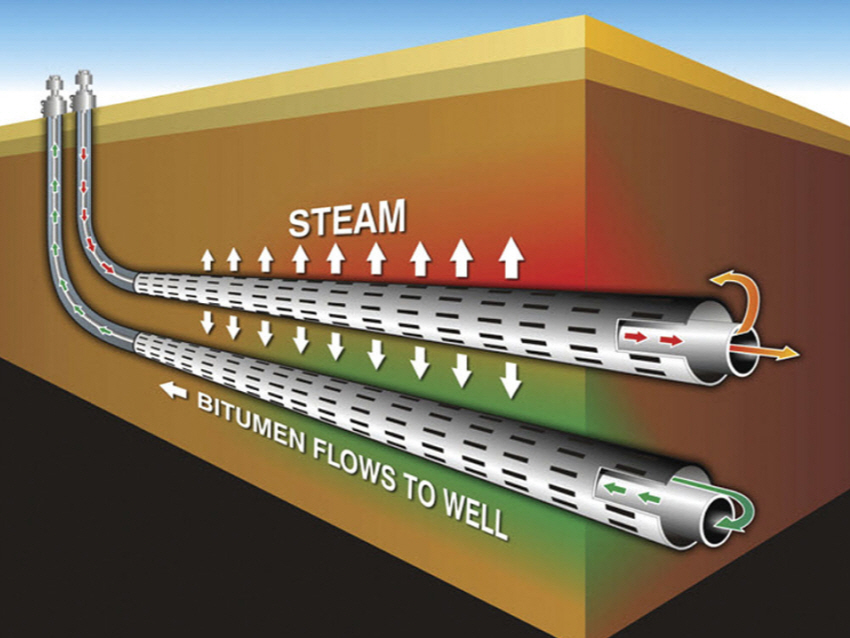

Well screen machines make sand control screens for horizontal downhole well installations using the SAGD (Steam Assisted Gravity Drainage) process. This process is used to extract extremely thick oil deposits, or bitumen, that is too deep for surface mining. Oil sand can be found in several locations around the globe, including Venezuela, the United States and Russia, but the Athabasca deposit in Alberta, Canada is the largest, most developed and utilizes the most technologically advanced production processes.

The screens keep particles larger than the slots in the screen from entering the well and damaging downstream pumps and equipment. The slots must be maintained as consistently as possible over the entire length of the 40-foot pipes. In order to achieve the best possible consistency, we convinced the customer to let us design the new machines in a particular way that was a radical departure from how these machines had always been built. The results were remarkable! After extensive measurements and testing it became clear that the new machines were much more consistent because of the way they were designed. This enabled the customer to produce an exclusive, premium product, and to compete in markets they would not have been able to otherwise. These machines deliver +/- 0.0015 inch, or better, slot consistency over 99% of the length of 40 foot pipes, which enables our customer to produce the most accurate and consistent well screens in the industry.

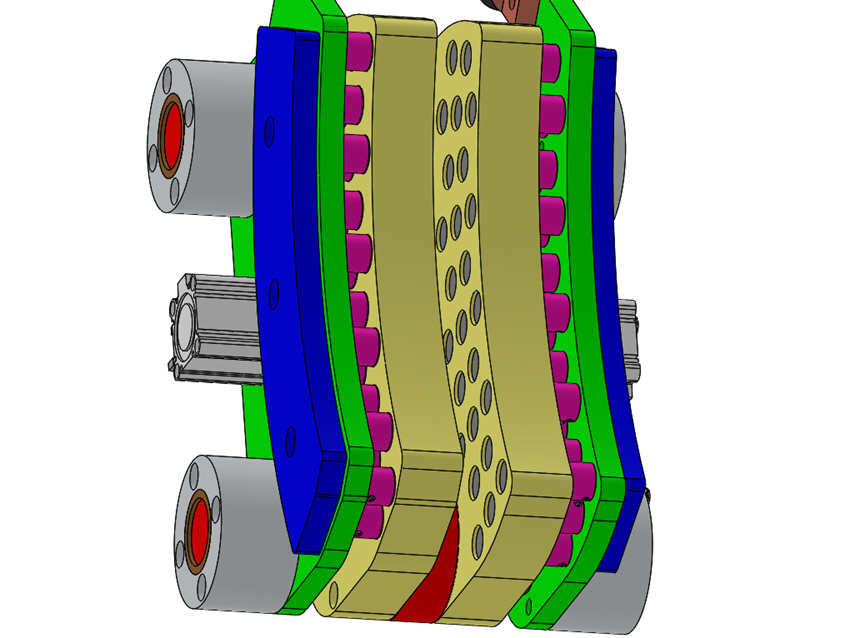

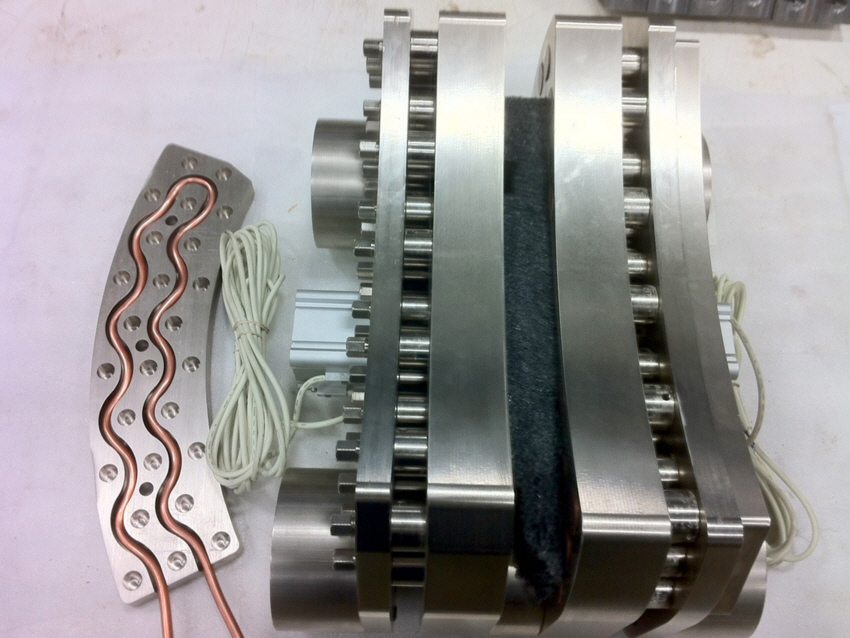

The welding force applied by the weld heads on the customer’s previous machines was inconsistent. We designed these machines so that the welding force is controlled precisely to within +/- 5 lbf. The force is applied consistently around the full circumference of the pipe, and is unaffected by out of round pipe. Thanks to this design the customer reported excellent weld penetration and consistently superior weld strength than they had experienced on previous machines.

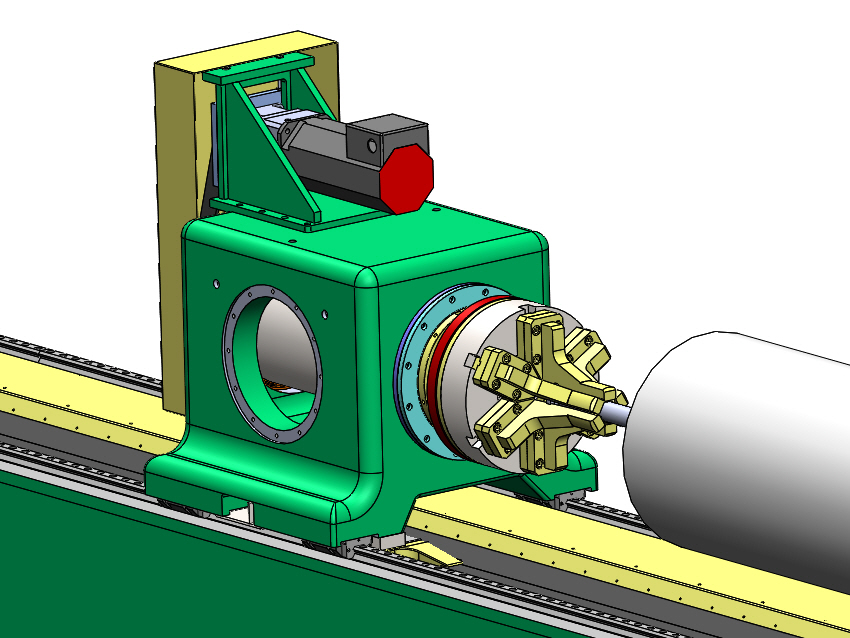

The customer had experienced significant vibration and tailstock deflection on their old machines when running wrap on pipe. The problems were so severe that the tailstock linear guide bearings were being damaged when running pipe, and had to be replaced frequently. After analyzing the problem, we determined that the tailstock linear bearings on their old machines had inadequate capacity to withstand the forces generated when running pipe, so we designed their new machines with much heavier, widely spaced linear bearings. We also designed the headstocks and tailstocks out of cast iron with 4 inch minimum wall thickness, along with wide widely spaced spindle bearings and self centering pipe chucks. Vibration was eliminated on the new machines, regardless of whether they were running pipe or jackets.

The machines have the capacity to produce screen jackets up to 26″ O.D. x 40 feet long, in addition to wrap on pipe with couplings up to 8.75″ O.D. Tailstocks are equipped with six-jaw self-centering chucks with special jaws we designed to swallow 8.75″ O.D. pipe couplings screwed onto 8″ O.D. pipe, which can quickly be switched over to 2.5″ O.D. jacket puller bars. Other specially designed components include liquid cooled weld head and current caliper with continuous capacity of more than 10,000 amps.